Introduction to Pneumatic Actuators

Pneumatic actuators are essential components in modern industrial automation, offering reliable performance through compressed air power. Their popularity stems from excellent force-to-speed ratios, cost-effectiveness, and robust operation. These devices play a crucial role in manufacturing, processing, and automation applications where consistent, reliable motion is required.

Key Selection Criteria

1. Force Direction Requirements

The direction of force needed is a fundamental consideration when selecting a pneumatic actuator. This choice primarily affects whether you need a single-acting or double-acting cylinder:

Single-Acting Cylinders:

- Utilize one air port for compressed air entry

- Move in a single direction using air pressure

- Return to starting position via spring mechanism

- Ideal for simple push/pull operations

- More energy-efficient for applications requiring movement in one direction

Double-Acting Cylinders:

- Feature air ports at both ends

- Provide controlled movement in both directions

- Offer more precise control over motion

- Better suited for applications requiring bidirectional force

- Generally more versatile but require more complex control systems

2. Load Requirements

Understanding the load requirements is crucial for proper actuator sizing:

- Force Calculation: Piston surface area × supplied air pressure = theoretical force

- For single-action cylinders, subtract the return spring force

- Consider both static and dynamic loads

- Factor in acceleration and deceleration requirements

- Include safety margins in load calculations

- Account for friction losses and system inefficiencies

3. Travel Distance Specifications

The required stroke length significantly influences actuator selection:

Rod-Type Actuators:

- Better suited for extension operations

- Longer stroke lengths available

- More traditional design

- Generally more economical for longer strokes

Rodless Actuators:

- Stroke length approximately equals assembly length

- Higher load-carrying capacity

- More compact design

- Better suited for space-constrained applications

4. Space Constraints

Available space often dictates actuator selection:

- Consider both extended and retracted positions

- Account for mounting requirements

- Factor in maintenance access

- Evaluate environmental conditions

- Consider integration with existing equipment

5. Control Requirements

Different applications require varying levels of control:

Precision Control:

- Rodless actuators offer better accuracy

- Suitable for applications requiring repeatability

- Better position control capabilities

- Often include integrated position sensing

Speed and Force Priority:

- Traditional rod-type actuators may be preferred

- Simpler control systems required

- More cost-effective for basic operations

- Better suited for high-speed applications

Additional Considerations

Environmental Factors

- Operating temperature range

- Exposure to contaminants

- Humidity levels

- Explosive or hazardous environments

- Cleaning requirements

Maintenance Requirements

- Accessibility for service

- Lubrication needs

- Seal replacement intervals

- Spare parts availability

- Mean time between failures

Cost Considerations

- Initial investment

- Installation costs

- Operating expenses

- Maintenance requirements

- Expected service life

Safety Requirements

- Emergency stop capabilities

- Fail-safe operation

- Protection against unexpected movement

- Compliance with safety standards

- Risk assessment requirements

Conclusion

Selecting the right pneumatic actuator requires careful consideration of multiple factors. While force requirements, travel distance, and space constraints are primary considerations, factors such as environmental conditions, maintenance needs, and safety requirements should also influence the final decision. Working with experienced suppliers and conducting thorough application analysis will ensure optimal actuator selection for your specific needs.

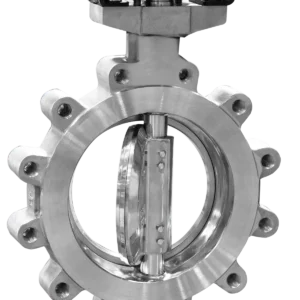

![BV89OEP-45-BUTTERFLY VALVE [2 WAY]-for industrial use](https://geotechsynergy.com/wp-content/uploads/2025/01/Capture-5-1-2.png)