Poppet valves are essential components in various industrial applications, particularly those requiring high flow rates and rapid response times. This article explores the working principle, design, and applications of poppet valves, focusing on the Maxseal range offered by MGA Controls.

Poppet Valve Working Principle Explained

The working principle of a poppet valve centers around a disk-shaped component (the poppet) attached to a movable stem. This mechanism operates similarly to a sink plug:

- When the stem lifts the poppet, it creates an opening that allows fluid to flow through

- When the stem pushes the poppet down, it forms a tight seal against the valve seat, stopping flow

This poppet valve function enables precise control over fluid movement through various actuation methods including solenoid, pilot, or manual operation.

How Does a Poppet Valve Work in Different Applications?

Poppet valve working varies slightly across industries:

- Engine Systems: Regulates intake and exhaust gas cycles within cylinders

- Industrial Processing: Controls directional flow in high-pressure environments

- Explore poppet valve applications in your industry →

Poppet Valve Types: Finding the Right Solution

Different poppet valve types offer specialized performance characteristics:

- Direct-Acting: Immediate response for critical applications

- Pilot-Operated: Enhanced efficiency for higher flow requirements

- Normally-Open/Normally-Closed: Various default positions based on safety requirements

- Compare all valve poppet configurations →

Maxseal Poppet Valves: Industry-Leading Performance

Our premium valve collection includes the complete Maxseal range, engineered for demanding environments:

Maxseal ICO2S Series

The Maxseal ICO2S represents the pinnacle of poppet valve engineering with:

- Robust construction for harsh conditions

- Exceptional pressure handling capabilities

- ATEX certification for hazardous environments

- Precise flow control characteristics

Additional Maxseal Options

Our extensive catalog includes:

- ICO3S Series: 3/2-way direct-acting valves with stainless steel construction

- ICO4S Series: Available in 2/2, 3/2, or 5/2-way configurations handling pressures up to 414-bar

- View all Maxseal poppet valve options →

Understanding Poppet Valve Working for Your Application

The poppet valve definition extends beyond basic functionality—these components are critical for:

- Ensuring system reliability in high-pressure environments

- Maintaining precise flow control under variable conditions

- Providing rapid response when immediate actuation is required

Complete Your Flow Control System

Looking for complementary flow control solutions? Browse our selection of:

Ready to implement optimal poppet valve solutions in your operations? Contact our valve specialists for personalized recommendations and technical support.

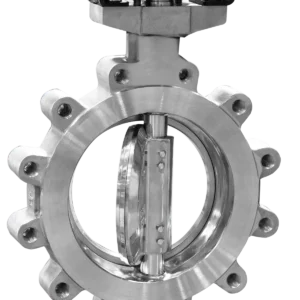

![BV89OEP-45-BUTTERFLY VALVE [2 WAY]-for industrial use](https://geotechsynergy.com/wp-content/uploads/2025/01/Capture-5-1-2.png)